Electrostatic oil cleaner

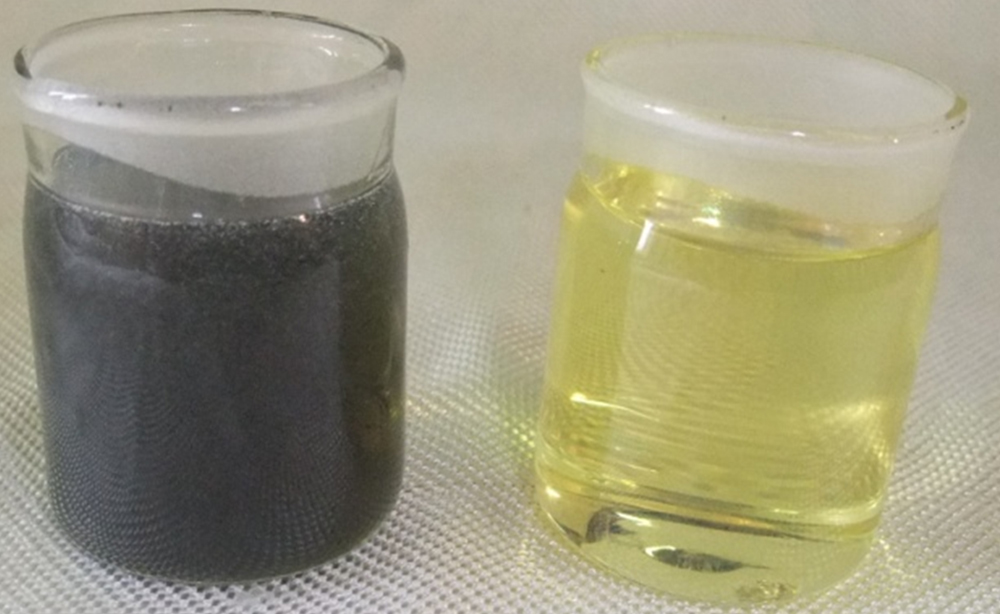

The operation of various machines and systems such as gas turbines, radial blowers, etc. causes the contamination of oil in the oil supply systems through mechanical wear particles and foreign substances, particularly water.

APPLICATION

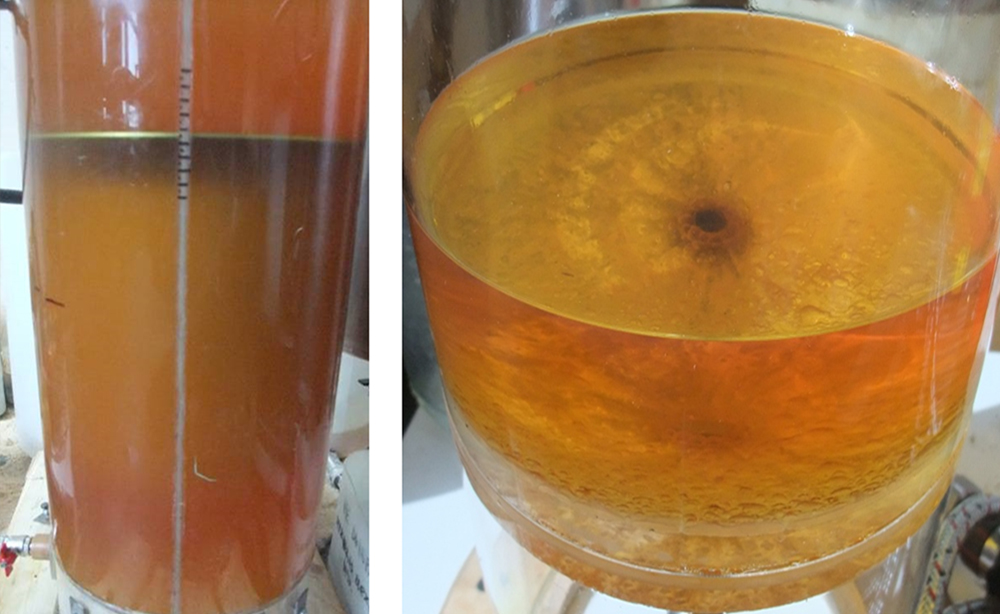

The electrostatic oil cleaner OME01-03 is designed to clean non-conductive fluids such as technical oils used within control, lubrication and sealing systems of turbines and similar equipment. Its use can also be extended to maintain oil in oil facilities of the gas transportation and energy industries.

GENERAL TECHNICAL DESCRIPTION

The oil cleaner consists of a coalescence pre-treatment module, a sorption-type dehydration module, an electrostatic cleaning module, a control panel, piping with shut-off valves and an electric pump. All equipment is placed in a leak-tight pan and mounted on a movable skid. The unit is equipped with level transmitters, water content detectors, and electric drive shut-off valves for automated operation.

Main technical characteristics of OME01-03

| Parameter | Unit | Value |

| Length | mm | not more than 1600 |

| Width | mm | not more than 800 |

| Height | mm | not more than 1500 |

| Unit weight | kg | not more than 400 |

| Oil temperature | °С | 10-70 |

| Oil viscosity | cSt | 1-100 |

| Capacity | l/h | 500 |

| Purity class according to ГОСТ 17216; NAS 1638; ISO 4406 |

- | 6; 3; -/11/9 |

| Water content | % | not more than 0.001 |

| Biological contamination | % | not more than 0.001 |

| Power supply | - | 380 V, 3 phase, 50 Hz |

| Maximum power requirement | kW | 1.5 |

OME01-03 FEATURES:

- Mobility, compact size

- Possibility of strapping

- Low energy consumption

- Alarm system and main parameter monitoring

- Option to operate the cleaner in stand-alone mode (connection to and disconnection from the oil supply system during turbine/machine operation)

- Components in contact with oil made of stainless steel, oil- and petrol-resistant rubber

- Quick-release leakage-free couplings for fast connection and disconnection of hoses

- Different dielectric fluids cleaning

- Oil ageing slowdown